■ The Hoist Spindle is one of the main parts of the main shaft device. It bears the weight of the entire main shaft device, external load and transmits all torque. It is forged with high-quality medium carbon steel or low alloy steel. One or two flanges are directly forged on the shaft, and are connected with the friction wheel through high-strength bolts. In order to reduce the stress concentration, the concave corners are used at the small corners.

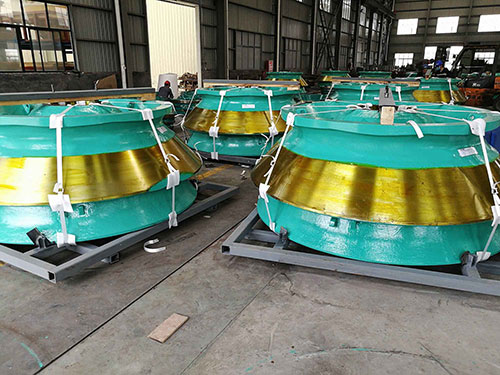

■ The main bearing is a supporting component that bears the weight of the entire main shaft device and all the loads on the wire rope. It is composed of rolling bearings, bearing covers, bearing housings, bearing end covers and other components. The two rolling bearings generally use cylindrical column holes, double-row radial spherical roller bearings, this bearing has good self-aligning performance, can bear larger radial loads and impact resistance, and can also withstand a small amount of axial force. Long service life, high efficiency, easy maintenance, lower requirements for installation errors and spindle deflection.

■ Due to the different stress conditions of tower multi-rope friction hoist and floor-type multi-rope friction hoist, the materials used for bearing housing and bearing cover are different, and the structure is also different. The end cover of each main bearing has both upper and lower parts Oil holes, used for filling and draining oil when cleaning bearings.

■ The main bearing is a supporting component that bears the weight of the entire main shaft device and all the loads on the wire rope. It is composed of rolling bearings, bearing covers, bearing housings, bearing end covers and other components. The two rolling bearings generally use cylindrical column holes, double-row radial spherical roller bearings, this bearing has good self-aligning performance, can bear larger radial loads and impact resistance, and can also withstand a small amount of axial force. Long service life, high efficiency, easy maintenance, lower requirements for installation errors and spindle deflection.

■ Due to the different stress conditions of tower multi-rope friction hoist and floor-type multi-rope friction hoist, the materials used for bearing housing and bearing cover are different, and the structure is also different. The end cover of each main bearing has both upper and lower parts Oil holes, used for filling and draining oil when cleaning bearings.

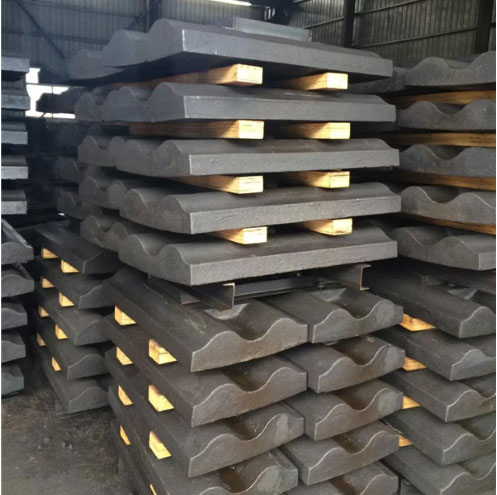

■ Forming Process: Forging + Finishing.

■ Heat Treatment: Normalizing + Tempering.

■ Material: 45MnMo.

■ Heat Treatment: Normalizing + Tempering.

■ Material: 45MnMo.

■ Mechanical properties: yield strength: 320-400mpa, tensile strength: 600-650mpa, area shrinkage: ≥ 45%, elongation ≥ 20%.

■ Hardness: HB163-217.

■ Weight: 5-50t.

■ Brand: CITIC, HENGIN.

■ Hardness: HB163-217.

■ Weight: 5-50t.

■ Brand: CITIC, HENGIN.