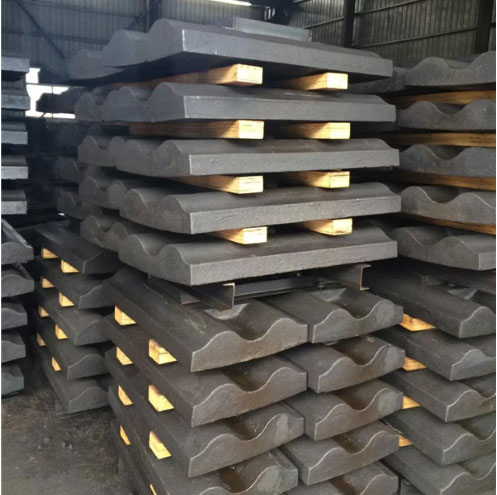

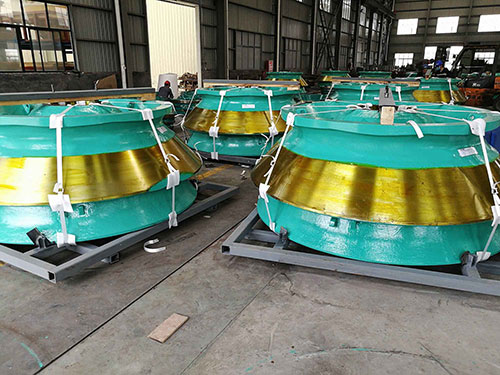

HENGIN'S Cr-Mo alloy and high chromium cast iron ball mill liners,rod mill liners have undergone continuous design improvements, optimized manufacturing processes, and improved mechanical properties. So as to maximize the service life of the ball mill.Our Φ2-Φ7.9m OEM CITIC, NHI Ball Mill Liners and Rod Mill Liners are used in the first and second stage ball mills in iron ore, copper ore, molybdenum ore, gold ore, phosphate ore and other fields.

■ Ball Mill/ Rod Mill Liner Design

According to the parameters of grinding mineral, such as feed particle size, mineral hardness and processing capacity, the paper designs the waveform structure and waveform quantity of the liners, and verifies them with DEM software, so that the design parameters of the liner structure are more accurate.

■ Material

◆ Cr-Mo Alloy Ball Mill Liner-A (wt%)C:0.80~0.90%,Mn:0.55~1.0,Si:0.40-0.60,Cr:1.90-2.50%,Mo:0.25-0.40%,S≤0.04,P≤0.04;

◆ Cr-Mo Alloy Ball Mill Liner-B (wt%) C:0.60~0.75%,Mn:0.55~1.0,Si:0.30-0.50,Cr:1.55-1.95%,Mo:0.25-0.45%,S≤0.04,P≤0.04;

◆ High Chromium Ball Mill Liner (wt%) C:2.5~2.9%,Mn:0.5~1.0%,Si≤1.0%,S≤0.03%,P≤0.04%,Cr:15.0~17.0%,Mo:0.5~3.0%,Ni:0.1~0.5%,Cu:0.25~1.0%,Ti:≤0.033%,V:0.01~0.5%.

◆ High Chromium Mill Liner (wt%) C:1.7~2.0%,Mn:0.8~1.0%,Si:0.3~0.6%,S≤0.035%,P≤0.035%,Cr:11.5~13.5%,Mo:0.5~0.7%,Ni:≤1.0%,Cu:≤0.25%,Ti:≤0.033%,V:≤0.25%.

|

Ball Mill* |

|||

|

Feed Head |

Shell |

Discharge Head |

Grate |

|

|

High Chrome Iron |

Pearlitic Cr-Mo Steel |

Pearlitic Cr-Mo Steel |

|

Wear resistant weldable plate |

|

Ni Hard |

|

|

Pearlitic Cr-Mo Steel |

|

|

|

■ Microstructure and Mechanical Properties

◆ Cr-Mo Ball Mill Liner Microstructure:Pearlite,

◆ High Cr Ball Mill Liner Microstructure:Tempered Sorbite, Martensite.

◆ Mechanical properties (sample test)

◆ Pearlite: HB325-370, σB≥850MPa, σS≥1000MPa, AK≥30J;Martensite: HRC50-55.

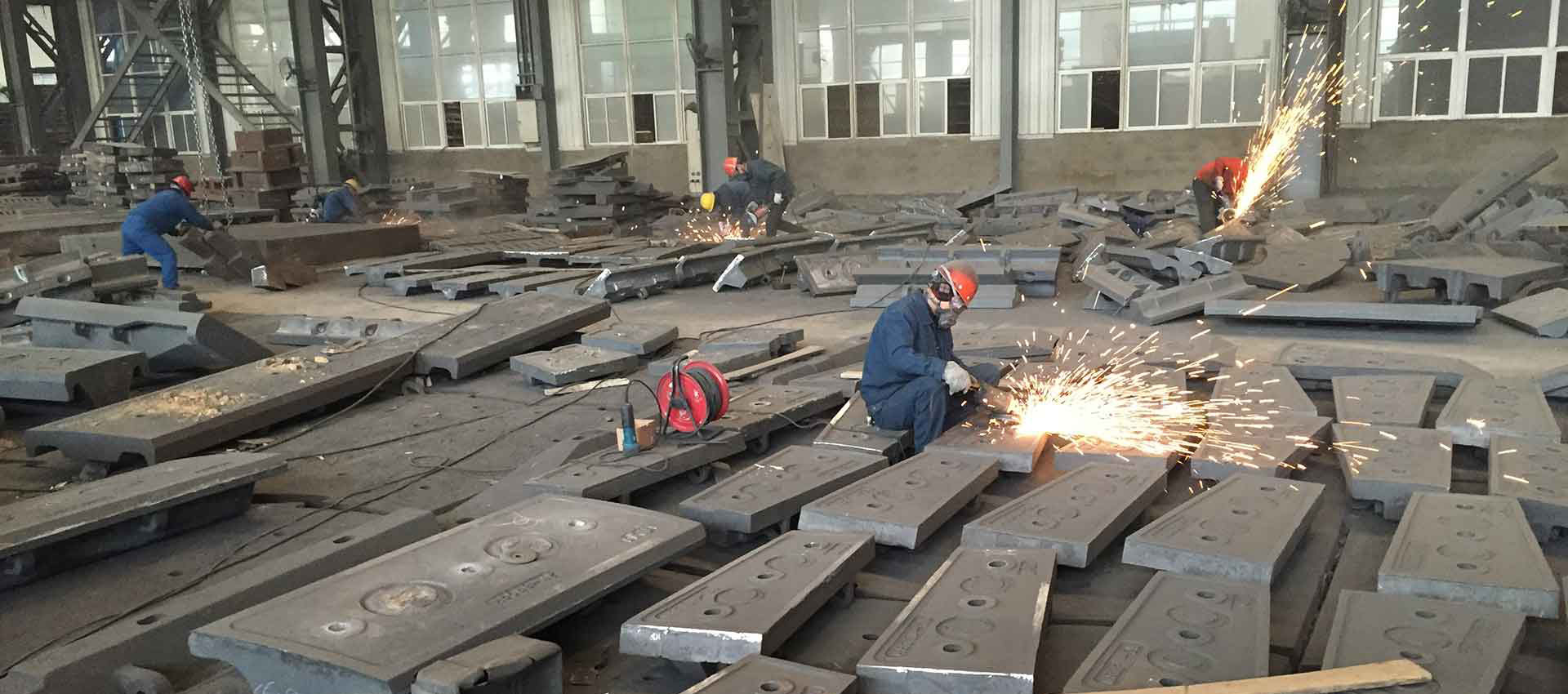

■ HENGIN Ball Mill Liner Casting Technology

Using experience parameters and ProCAST aided design of precision casting parameters.

◆ Model: Wood model.

◆ Casting Molding:Phenolic resin sand molding ensures that the lining board surface is smooth and the size is accurate.

◆ Molten steel smelting

Medium frequency electric furnace smelting molten steel, refining outside the furnace.

■ Heat Treatment

Normalizing + Tempering.