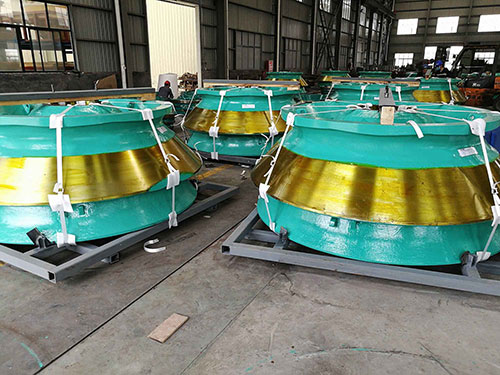

Rotary kiln Girth Gear is installed on the rotary kiln shell, which is generally installed near the Block Roller and Support Roller. It transmits the power of the transmission part to the shell. It is one of the largest force-bearing parts in the rotary kiln equipment, Girth Gear and shell Adopt welded spring plate or pin-type spring plate connection, which can buffer the gear and gearbox.

Rotary Kiln Girth Gear and Cement Mill Girth Gear from HENGIN are mainly used in the large-scale rotary kiln and mill equipment of OEM CITIC,Sinoma,FLSmidth,NHI,Pengfei,Mesto and other brands, with long life cycle and high cost performance.

■ Applicable equipment: Cement Rotary Kiln,Cement Mill, Pellet Rotary Kiln, Dryer;

■ Manufacturing and Testing Standards: GB / T 32994-2016, ANSI / AGMA6114-A06;

■ Rotary Kiln Girth Gear Diameter: 3-11m;

■ Module: 20-50;

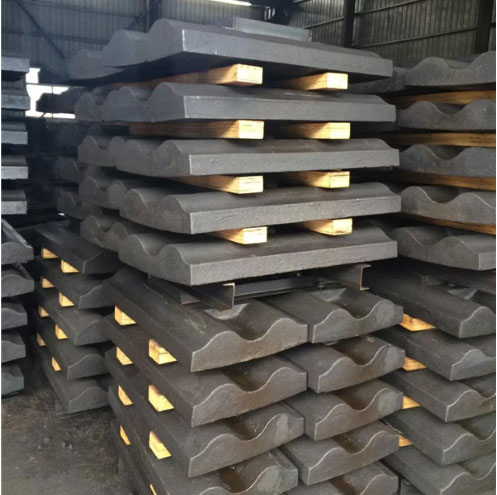

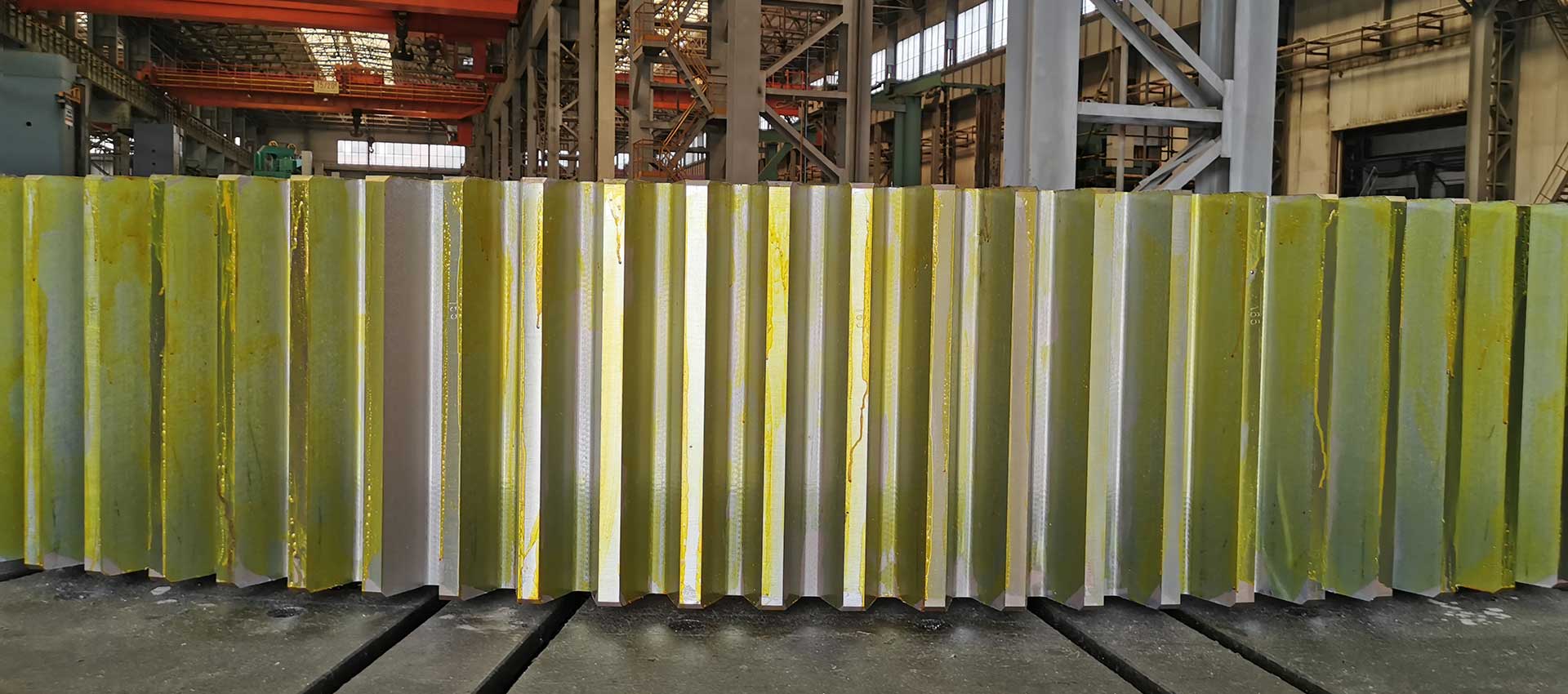

■ Manufacturing Process: Casting, Machining;

■ Girth Gear Material:42CrMo,35CrMo,ZG230-450,ZG270-500;

■ Heat Treatment Method: Normalizing or Quenching and Tempering;

■ Heat Treatment Hardness: HB210-300;

■ Girth Gear NDT: Rough Machining, UT, MT Inspection after Finishing;

■ Structure: whole, 2-valve, 3-valve,4-valve;

■ Weight: 3-70t;

■ Applicable Rotary Kiln Brands: Sinoma, FLSmidth,CITIC,NHI, Pengfei,Mesto.