|

|

|

1.Ingot Mould for Crusher Spindle

|

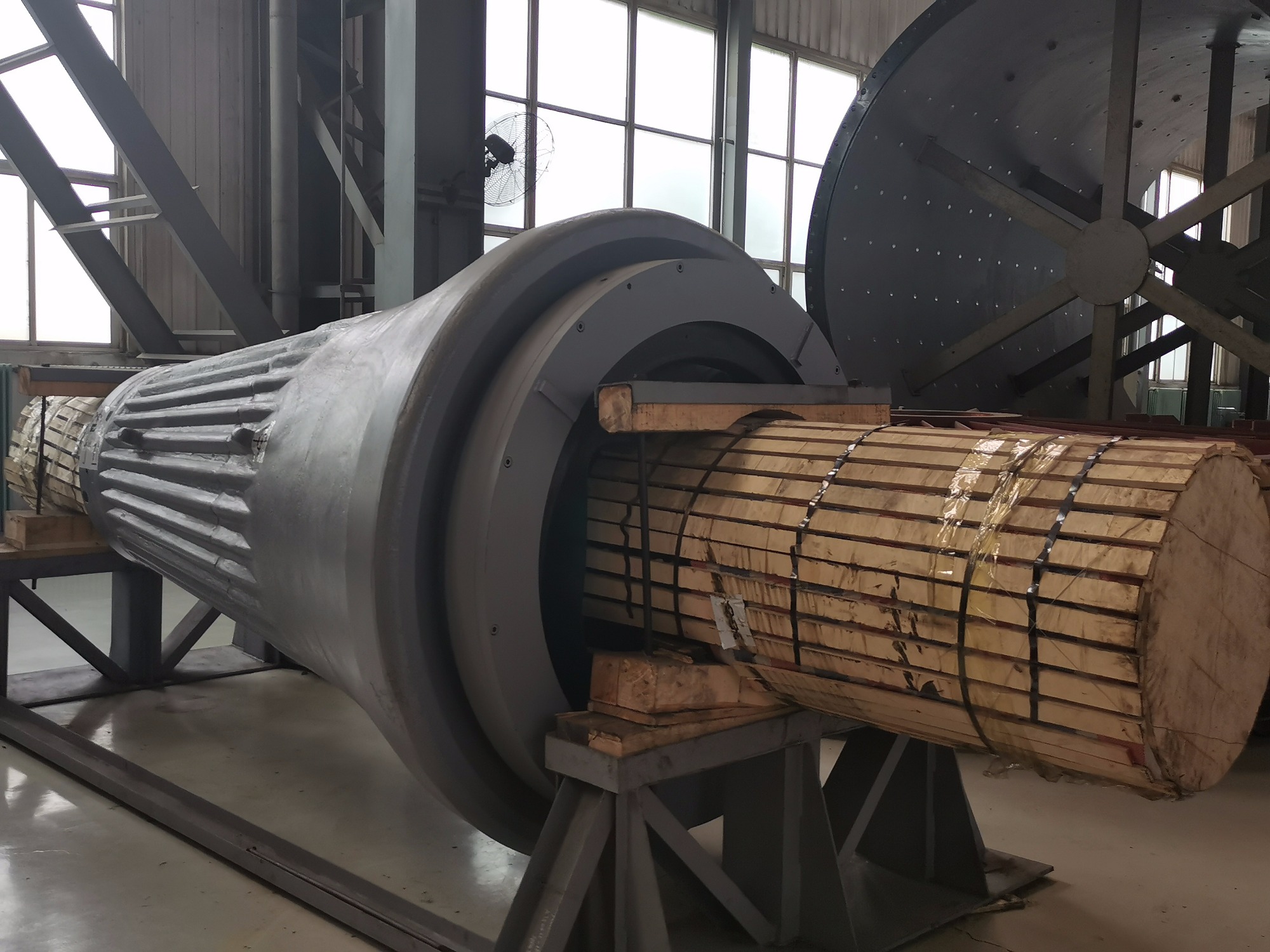

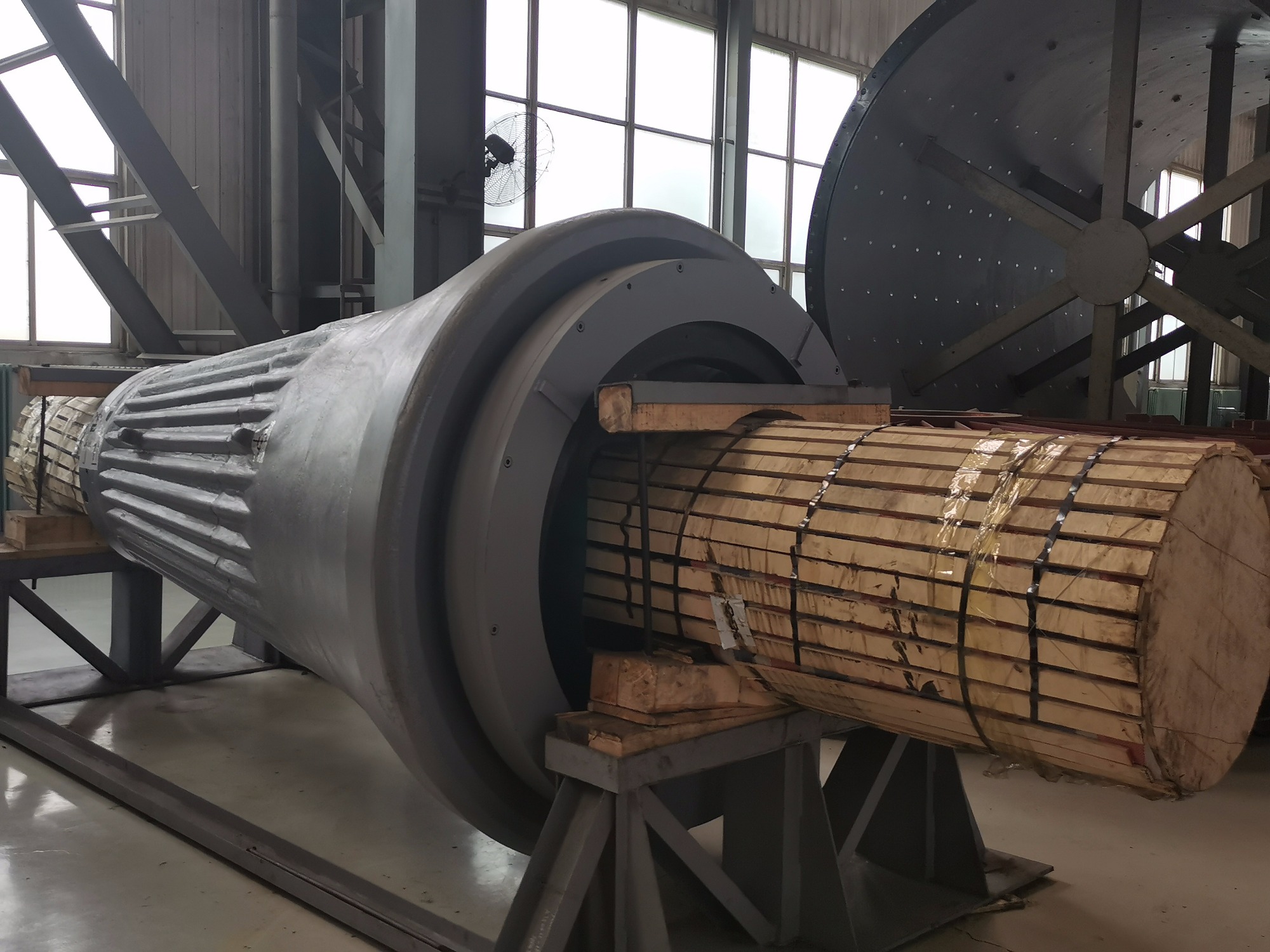

2.Crusher Spindle Casting

|

3.Rotary Crusher Spindle Forging

|

|

|

|

| 4.Rough Machining |

5.Spindle Finishing |

6.Spindle Assembly |

■ Casting process

The main shaft of crusher for large-scale ingot casting process is produced by EAF primary smelting → LF refining → VCD vacuum treatment →VC vacuum pouring ingot → Forging.

■ Forging process

Pressure clamp→ Pre-drawing →Upsetting, drawing →Rolling → Drawing to finished products.

■ Performance heat treatment process

Normalizing→ Tempering→ Air cooling out of furnace→ Dimension and hardness testing of each part→ Taking performance test rods.