■ Hot-Rolled Sheet Main Drive Gearbox

◆Performance characteristics

Optimized gear modification technology with high rigidity

◆High torque transmission

Carburized and hardened welded gears with hard tooth surfaces reduce weight

◆The main technical parameters

◆Rated power: up to 12,000 kW

◆Number of levels: one or two levels

◆Speed Ratio: 1–10

◆Torque: up to 4,200 kN.m

◆Main application areas

Mainly used in hot continuous rolling, continuous casting and continuous rolling plate rolling production line.

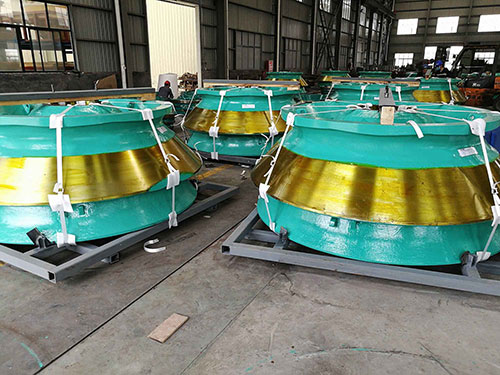

■ Planetary Differential GearboxThe gearbox of XCJ series port ship unloader adopts planetary differential gearbox, which is applied to the four-drum drive system of bridge grab ship unloader. The input motion of the closing motor and the walking motor is transformed into different rotation directions of the four drums and the combination of different speeds of movement, so as to control the lifting, opening, closing and walking of the grab. The key core equipment of marine aircraft.

◆Performance characteristics

◆Special design to meet the requirements of different working conditions.

◆Compact structure and large carrying capacity.

◆Gear modification, large contact ratio of tooth surface, low noise.

◆Mechanical seal, easy to use and maintain.

◆Large selection of center distance.

◆The main technical parameters.

◆Specification: XCJ

◆Transmission Ratio: 11.2–50.

◆Maximum loading and unloading capacity: 5,000t / h.

◆Center distance between two output shafts: 800–2,800 mm.

◆Main application areas.

◆Bridge grab ship unloader.