■ HENGIN'S Pinion Products Include

Gear Box: mill, rolling mill, railway, wind power, etc, reducer gear box pinion;

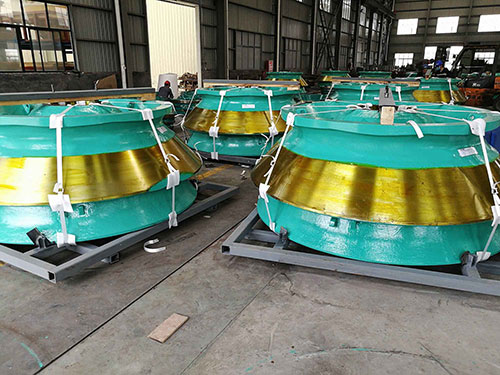

Grinding Mill Pinion: Ball mill,SAG mill ,Rod mill;

Pellet Rotary Kiln Pinion; rotary kiln pinion, cement mill pinion;

■ Manufacturing Standards and Materials

◆ AG2101-d04 and AGMA 6114;

◆ 17CrNiMo6,20CrNi2MoA,30Cr2Ni2Mo;

◆ 34CrNi3Mo,42CrMo;

■ Carburizing Gear Accuracy

AGMA 2101-d04, AGMA 6114 and grade 5 (A5) in AGMA 2015, and the precision of quenched and tempered pinion reaches Grade 7 (A7) in AGMA 2101-dq4, AQ4A6114 and AGMA 2015;

■ Grain Size Standard

It shall meet the requirements of ASTM E112 test sample or test bar. The grains and non-metallic inclusions (purity) reaching grade 5 or finer shall be inspected in accordance with ASTM E45 and meet the requirements of AGMA 6114 standard;

■ Microstructure Standard

The carbon concentration on the surface, the metallographic structure of the surface, the structure of the carbon flood layer, the carbide precipitation, the retained austenite and the metallographic structure of the core shall be inspected according to the appropriate standards, and shall conform to the M2 level and AGMA 2101-d04 in article 11-15 of table 7 of AGMA 6114 standard;

■ Weight:50-6000Kg;

■ Pinion Module and Accuracy

Module range: M10-M30; accuracy: above DIV4 Class;

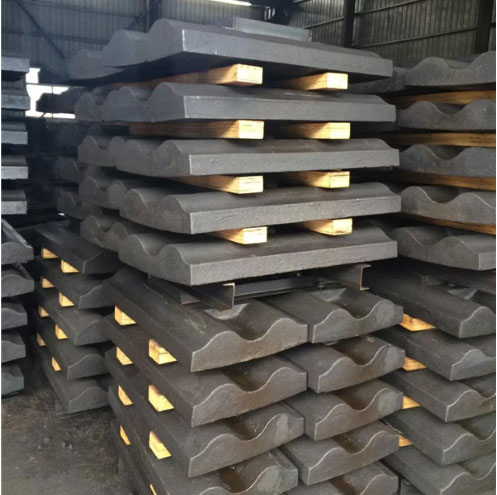

■ Manufacturing Process

Forging → Roughing → Heat Treatment→NDT → Finishing → Combing → Grinding → Carburizing → NDT → Packaging;

■ Pinion Manufacturing Equipment

CNC vertical lathe, horizontal lathe, machining center, vertical mill, cylindrical mill, Gleason gear hobbing machine, Niles and Gleason gear grinding machine, klinberg gear testing center and aixilin heat treatment production line, etc.