SAG mill liners from Hengin are based on working conditions and mine attributes to carry out structural design, material selection, casting process design, heat treatment process design, manufacturing, on-site tracking and mapping, and continuous optimization and adjustment. Our mining mill liners serve a wide range of users of iron ore, copper ore, molybdenum ore, gold ore, and uranium ore around the world with the quality of excellence.We are a service solution provider for the full life cycle of mining SAG mill liners,products mainly including feed head,mill shell,discharge head,slurry elevator liners. We also provide cost-effective OEM CITIC,FLSimdth SAG Mill Liners and other Mining Wear Parts for users worldwide.SAG Mill Liners from Hengin is made of Cr-Mo alloy, and its main matrix structure is pearlite and carbide. Cr-Mo mill liner has superior strength and toughness matching, which can meet the requirements of the liner to deal with the conditions of high wear resistance and high impact toughness. It is currently the main international material selection standard for Mine SA, SAG mill liners.

■ Hengin's Mining SAG Mill liner Design and Manufacturing

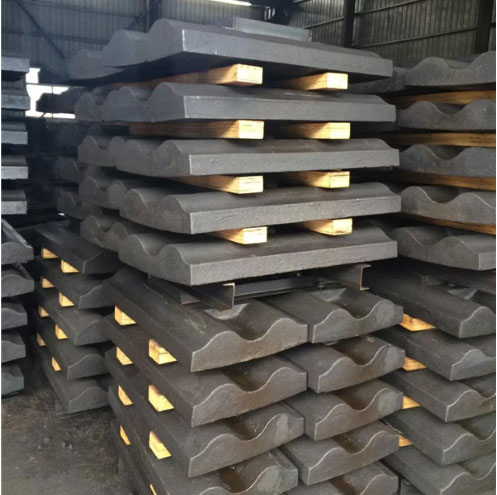

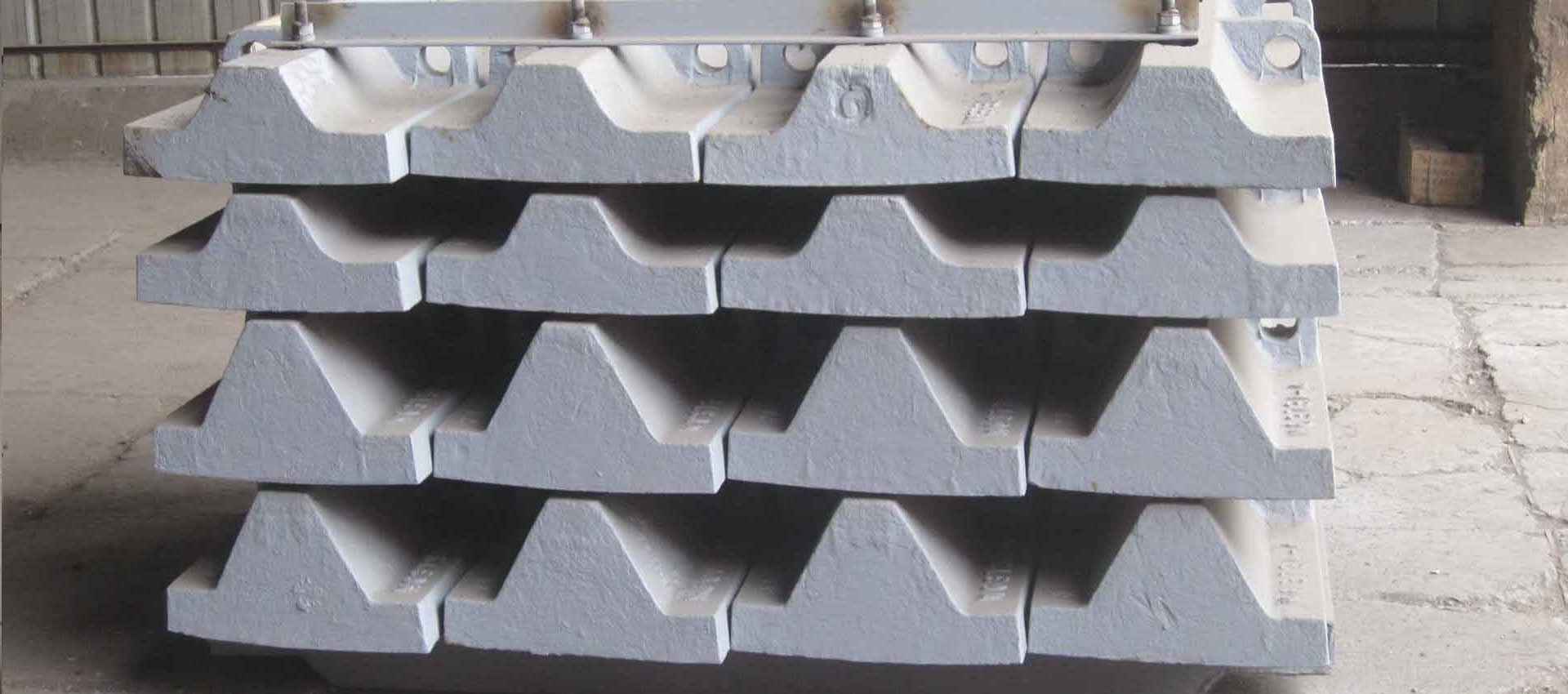

◆ SAG Mill Liners Casting

Casting Process Design→Model Making→Resin Mand Modeling→Molten Mteel Mmelting→Mouring→Molidification and Thermal Insulation Stress Relief→Cleaning and Polishing→Normalizing Heat Treatment→Shot Blasting→Packaging.

◆ SAG Mill Liner Design and Simulation

We use MilTraj and DEM software to design the SAG mill liner to accurately position the Toe. Use Procast software to simulate the casting of the liner to eliminate casting defects and ensure the quality of castings.

■ Hengin's Mining SAG Mill CrMo Liners Basic Information and Mechanical Properties

|

|

Casting Maximum Hot Pitch Circle |

Casting Dimension Accuracy Grade |

Microstructure |

Grain Size Level |

Weight/Kg |

Mill Liner Wear Form |

Cr-Mo Alloy |

250-300mm |

CT11-CT12 |

Pearlite + Carbide |

7-8 |

100-4500 |

Impact wear |

|

|

σb(Tensile Strength)/MPa |

A(Section Shrinkage)/% |

Ak(Impact Toughness)/J |

Hardness/HB |

≥850 |

950~1200 |

8-15 |

≥30 |

≥ 321-375 |

Our mining mill liners for CITIC, Tisco, Zijin Mining, China Gold, etc.Cr-Mo mill liners has been widely used in China, Australia and other places in copper, gold, iron, molybdenum and other mines.The hardness reflects the wear resistance of the liner. In order to resist the grinding effect of higher hardness metal ores, the Cr-Mo SAG mill liners of has higher hardness. At the same time, in order to ensure that the liners does not break under the strong impact of the ore and the grinding ball, the CrMo mill liner has high impact toughness.Because the mining mill liner of the is thicker. In order to achieve the uniformity of structure and performance, the mill Cr-Mo liner has high hardenability; in addition, the liner is immersed in corrosive media, and the Cr-Mo liner also needs to have high corrosion resistance.In short, mining SA and SAG mill liners should have good comprehensive mechanical properties, hardenability, corrosion resistance and wear resistance, and it is not suitable to pursue a single performance.

■ Hengin's Mining SAG Mill Liners Main Composition

✔ Large Mine SAG Mill Liners Standard

✔ Mine Mill Liners Analysis of Factors Affecting

✔ SAG Mill Liners Design

✔ SAG Mill Liners Casting

✔ SAG Mill Liners Casting Procast Simulation

✔ Mine Mill Liners Heat Treatment

✔ Mill Liners Inspection

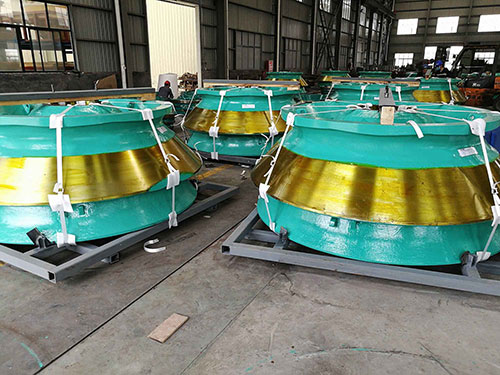

✔ Liners Display

✔ SAG Mill Liners Use

✔ Reasons for choosing Hengin's SAG Milll liner